LO2 LN2 LAr Cryogenic Tank

Founded in 2004, DSW is one of China’s most professional cryogenic tank suppliers, offering high quality at competitive prices.

Our main products are cryogenic liquid storage tanks, large flat cryogenic liquid storage tanks, cryogenic liquid pumps, and air vaporizers.

Cryogenic tanks store liquefied gases, known as cryogenic liquids, which are typically maintained at temperatures of -150 °C or colder.

These tanks commonly contain gases such as oxygen, argon, nitrogen, hydrogen, and helium.

Cryotanks

1. DSW supplies liquid oxygen tanks, lar cryogenic tanks, liquid nitrogen tanks, liquid nitrogen oxide, liquid carbon dioxide, and LNG tanks.

2. Tank capacity range: 2M3~350M3.

3. Cryo Tank pressure: 8bar, 16bar or based on user requirement.

4. International Certificates: GB, ASME, CE

5. Type: Vertical Cryogenic Tanks and Horizontal Cryogenic Tanks

6. Insulating mode: vacuum perlite powder and super vacuum multi-layer

We use a new material, strong stainless steel, to reduce the self-weight of the tank and raise its efficiency;

DSW provides non-standard size design services for clients.

Our tanks are used in gas, chemical, machinery, metallurgy, medical, nuclear power, and other industries.

Features of Cryo Tank

Inner vessel – stainless steel for cryogenic temperature with optimized design for lightweight

Outer Jacket – carbon steel exterior with a combined leg and lifting lug system designed for safe transport, easy lifting, and low-cost erection

Insulation – a proven high-quality vacuum-super insulation system ensures long-term vacuum performance, backed by a year’s warranty on vacuum integrity.

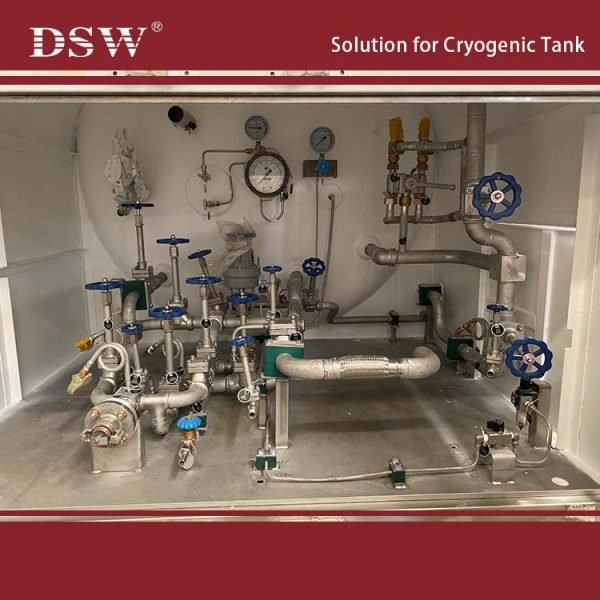

Piping – stainless steel piping for reliability and durability; ergonomically designed layout without flow diagram and gauges at eye level

Valves (Cryogenic Tank)– modular configuration bronze valves with welded-on connections (other valves, such as stainless steel and screw-on connections are optional)

Pressure Control – an easily adjustable multifunction regulator, economizer, and check valve is a pressure regulator. An aluminum pressure building coil is standard. Other types of PBUs, including high-capacity PBU or stainless steel core vaporizers, are optional.

Instrumentation – high-quality pressure gauge and differential pressure contents gauge are standard with optional switches, transmitter, and telemetry unit.

Safety – tanks with dual relief valves switching various options, including additional relief valves and rupture discs. Easily accessible valves and safety relief valve outlets directed away from the operating area.

Pump Options – A thermosiphon tank with a pump connection is available as an option

Cleanliness – all tanks and their components are cleaned and certified for oxygen service.

Outer Finish – high-grade sand-blasting and rust-removing painting with standard durable corrosion-resistant epoxy-polyurethane white paint

Transport – rugged internal supports for safe road, rail, or sea transportation.